Description

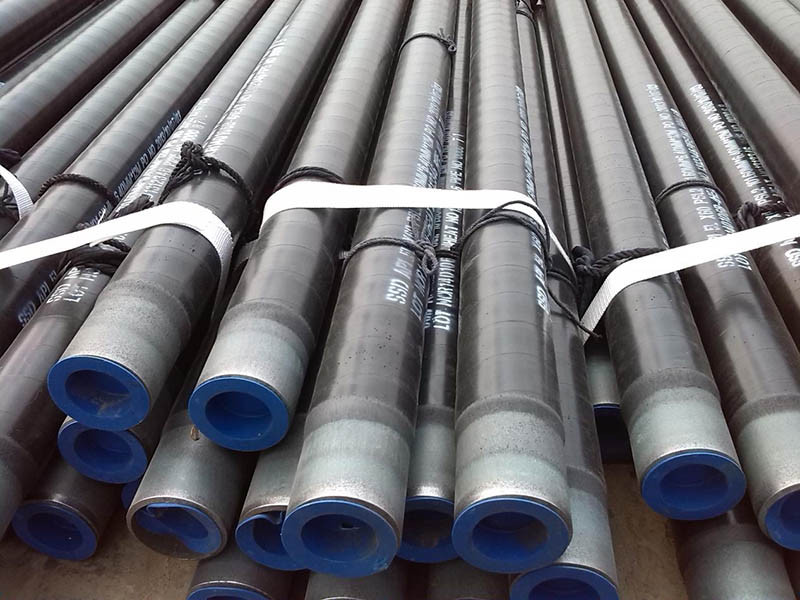

3PE anti-corrosion and thermal insulation steel pipe has good thermal insulation performance, and the heat loss is only 25% of that of traditional pipes. Long term operation can save relatively large resources, significantly reduce energy cost, and still have strong waterproof and corrosion resistance. Moreover, it does not need to be attached with pipe trench, so it can be directly buried in underground or water, which is also simple and rapid in construction, The comprehensive cost is also relatively low. It also has good corrosion resistance and impact resistance under low temperature conditions, and can be directly buried in frozen soil in a certain environment. Before the base metal of 3PE anti-corrosion steel pipe is subject to anti-corrosion treatment, the steel pipe entering the pipe inlet platform shall be inspected and recorded, the outer surface of the steel pipe shall be shot blasted for rust removal, and then the cleanliness and anchor depth of the outer surface of the steel pipe shall be inspected to see whether they meet the requirements. If they do not meet the requirements, they shall be polished and qualified with manual grinding wheel, wrapped with adhesive tape paper at the pipe end, treated with micro dust, and heated to the required temperature with medium frequency, Epoxy powder spraying, adhesive extruder side winding, PE extruder side winding, water cooling of anti-corrosion pipes, spraying identification of qualified products, pipe laying platform and stacking for shipment. Main equipment for manufacturing 3PE anti-corrosion steel pipe: steel pipe buffer platform, pipe pulling unit, tractor, pipe threading machinery, high-pressure blasting machine, repair platform, transmission line, steel pipe preheating furnace, main machine maintenance platform of shot blasting machine, return transmission line of branch grid steel pipe, fast forward roller group, fast out roller, maintenance platform, etc. The anti-corrosion operation production line of anti-corrosion steel pipe can be applied to the anti-corrosion operation of single-layer FBE, double-layer FBE, double-layer PE, double-layer PP and 3PE of steel pipe. Minimum machining pipe diameter Φ 89mm, maximum processing pipe diameter Φ 3020mm, with a maximum processing capacity of more than 350m2 / h. The production line includes steel pipe transmission system, surface treatment system, pipe dust removal system, steel pipe heating system, electrostatic spraying system, coating system, water cooling system, end cutting system, hydraulic and pneumatic system, detection system and electric control system 3P anticorrosive spiral steel pipe anticorrosive structure: the first layer of epoxy powder (FBE > 100um), the second layer of adhesive (AD) 170 ~ 250um, and the third layer of polyethylene (PE) 1.8 ~ 3.7mm. The three materials are integrated and firmly combined with the steel pipe to form an excellent anti-corrosion coating. Pipe diameter range Φ 60~ Φ 1420。 Two layer PE anticorrosive structure of 2PE anticorrosive pipeline: the first layer of adhesive (AD) and the second layer of polyethylene (PE). The two materials are integrated, and the thickness of each layer is the same as that of the three layers of PE.

Before the base metal of 3PE anti-corrosion steel pipe is subject to anti-corrosion treatment, the steel pipe entering the pipe inlet platform shall be inspected and recorded, the outer surface of the steel pipe shall be shot blasted for rust removal, and then the cleanliness and anchor depth of the outer surface of the steel pipe shall be inspected to see whether they meet the requirements. If they do not meet the requirements, they shall be polished and qualified with manual grinding wheel, wrapped with adhesive tape paper at the pipe end, treated with micro dust, and heated to the required temperature with medium frequency, Epoxy powder spraying, adhesive extruder side winding, PE extruder side winding, water cooling of anti-corrosion pipes, spraying identification of qualified products, pipe laying platform and stacking for shipment. Main equipment for manufacturing 3PE anti-corrosion steel pipe: steel pipe buffer platform, pipe pulling unit, tractor, pipe threading machinery, high-pressure blasting machine, repair platform, transmission line, steel pipe preheating furnace, main machine maintenance platform of shot blasting machine, return transmission line of branch grid steel pipe, fast forward roller group, fast out roller, maintenance platform, etc. The anti-corrosion operation production line of anti-corrosion steel pipe can be applied to the anti-corrosion operation of single-layer FBE, double-layer FBE, double-layer PE, double-layer PP and 3PE of steel pipe. Minimum machining pipe diameter Φ 89mm, maximum processing pipe diameter Φ 3020mm, with a maximum processing capacity of more than 350m2 / h. The production line includes steel pipe transmission system, surface treatment system, pipe dust removal system, steel pipe heating system, electrostatic spraying system, coating system, water cooling system, end cutting system, hydraulic and pneumatic system, detection system and electric control system 3P anticorrosive spiral steel pipe anticorrosive structure: the first layer of epoxy powder (FBE > 100um), the second layer of adhesive (AD) 170 ~ 250um, and the third layer of polyethylene (PE) 1.8 ~ 3.7mm. The three materials are integrated and firmly combined with the steel pipe to form an excellent anti-corrosion coating. Pipe diameter range Φ 60~ Φ 1420。 Two layer PE anticorrosive structure of 2PE anticorrosive pipeline: the first layer of adhesive (AD) and the second layer of polyethylene (PE). The two materials are integrated, and the thickness of each layer is the same as that of the three layers of PE.